Triologic

Facilitate Successful Mycorrhizal Colonization

What is it?

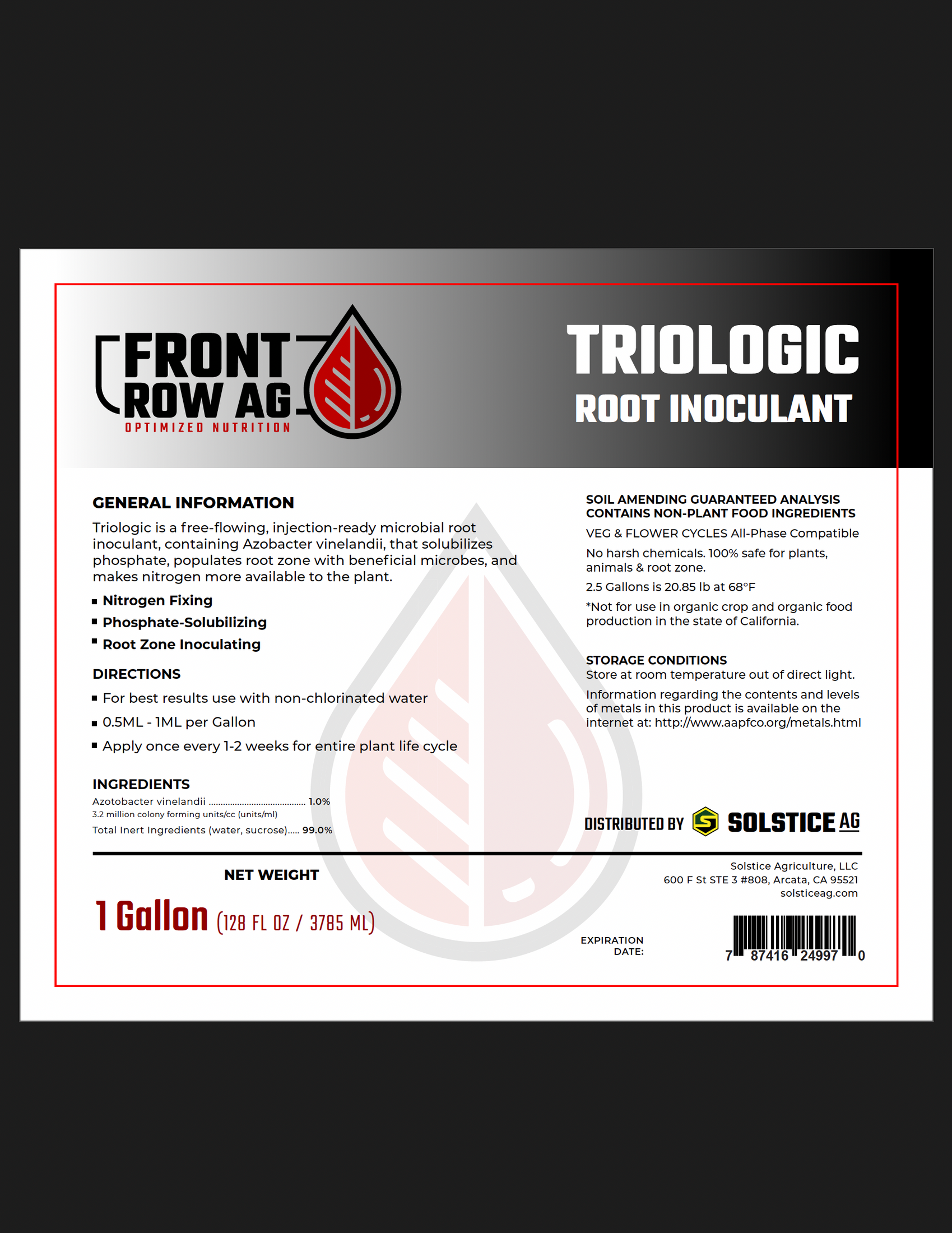

Triologic is a microbial root inoculant containing high concentrations of rhizobacteria that promote the uptake of essential minerals.

WHY USE IT?

The highly concentrated bacteria in Triologic work within the substrate to increase yield, improve fertility, and enhance resistance to pests and disease. Applying these bacteria to the rootzone early in a plant’s development can reduce the effects of abiotic stresses while making more efficient use of fertilizers.

How does it work?

Plant growth promoting rhizobacteria colonies in the substrate are able to fix nitrogen and cycle other essential nutrients, including Phosphorus and Potassium into forms easily available to the plant roots. Additionally, these beneficial bacteria can help supply nutrition to the mycorrhizae that are protecting the plants roots, aiding the formation of beneficial fungal colonies.

To learn more about how Triologic supports Mycorrhization, read our blog post on Triologic and Mycorrhizae here: frontrowag.com/blogs/info/trio-myco

Usage:

1-2 ml/Gal (0.26-0.53 ml/L), 1x per week.

Best used as a hand water drench.

Triologic Documents

Blog posts

The Importance of pH Management Across Crop Growth Stages

Why Electrical Conductivity Management Is Critical for Plant Hydration and Growth