Specialty produce and high-value floriculture require a strict balance of environmental variables to reach their full potential. While most managers focus on lighting and mineral concentrations, the temperature of the water in the reservoir is the metabolic throttle that controls how fast a plant can grow. Maintaining nutrient water roughly between 65 and 71 degrees Fahrenheit is the biological key to balancing dissolved oxygen levels with mineral solubility for maximum output. When environmental variables are mismanaged, even the most expensive lighting systems cannot save a crop from underperforming.

A lead grower walks through the facility early in the morning and notices the high-value specialty cultivars are looking sluggish. The high-output LED lights are bright, the carbon dioxide levels are perfect, and the fertigation system is delivering a high-strength recipe at a 3.0 EC exactly as the feed chart requires. Yet, the plants show purple stems and small leaves, and the expected growth explosion of the stretch phase has stalled. The manager checks the sensors and the substrate moisture, but everything looks correct on the computer screen. The problem is hidden inside the pipes.

In many commercial facilities, the nutrient water sits in supply lines that run along a cold concrete floor overnight. By the time that water reaches the crop, the temperature has dropped to 52 degrees. This is a cold stall.

Feeding a specialty crop with shivering water is like trying to drive a car with frozen engine oil. The liquid is present, but it is too thick and sluggish to move. Cold water stops the nutrient highway in its tracks, causing a metabolic bottleneck that no amount of light or extra fertilizer can fix. Understanding water quality is a multi-faceted endeavor that includes thermal management as a primary pillar of success.

How Reservoir Heat Impacts the Metabolic Engine

The data indicates a critical relationship between water temperature and dissolved oxygen. In any hydroponic water management strategy, dissolved oxygen is the fuel that allows roots to perform the work of mineral uptake. Roots act as the gatekeepers of the plant. To pull in minerals like potassium and calcium, the root cells must expend energy through a process called active transport. This process requires oxygen.

As water temperature in the hydroponic system rises, its ability to hold dissolved oxygen decreases. If the water exceeds 75 degrees, oxygen levels plummet, and the roots essentially begin to suffocate, leading to a total collapse of nutrient uptake efficiency.

On the other side of the spectrum, water that is too cold creates a different physiological barrier. High-value greenhouse produce relies on chemical reactions within the root zone to process minerals. When water is cold, these reactions slow down. Phosphorus becomes significantly more difficult for the plant to absorb in cold conditions. This leads to the characteristic purple tinting and slow growth seen in shivering crops.

Physiological principles show that the metabolic pump of the plant is temperature-dependent. By maintaining the root zone in a stable thermal window, you ensure the gatekeepers have both the oxygen they need to breathe and the thermal energy required to move minerals into the plant. Using a reliable feed chart allows growers to maintain mineral balance, but that balance only expresses fully within a specific thermal window.

Avoiding the Warm Reservoir Trap

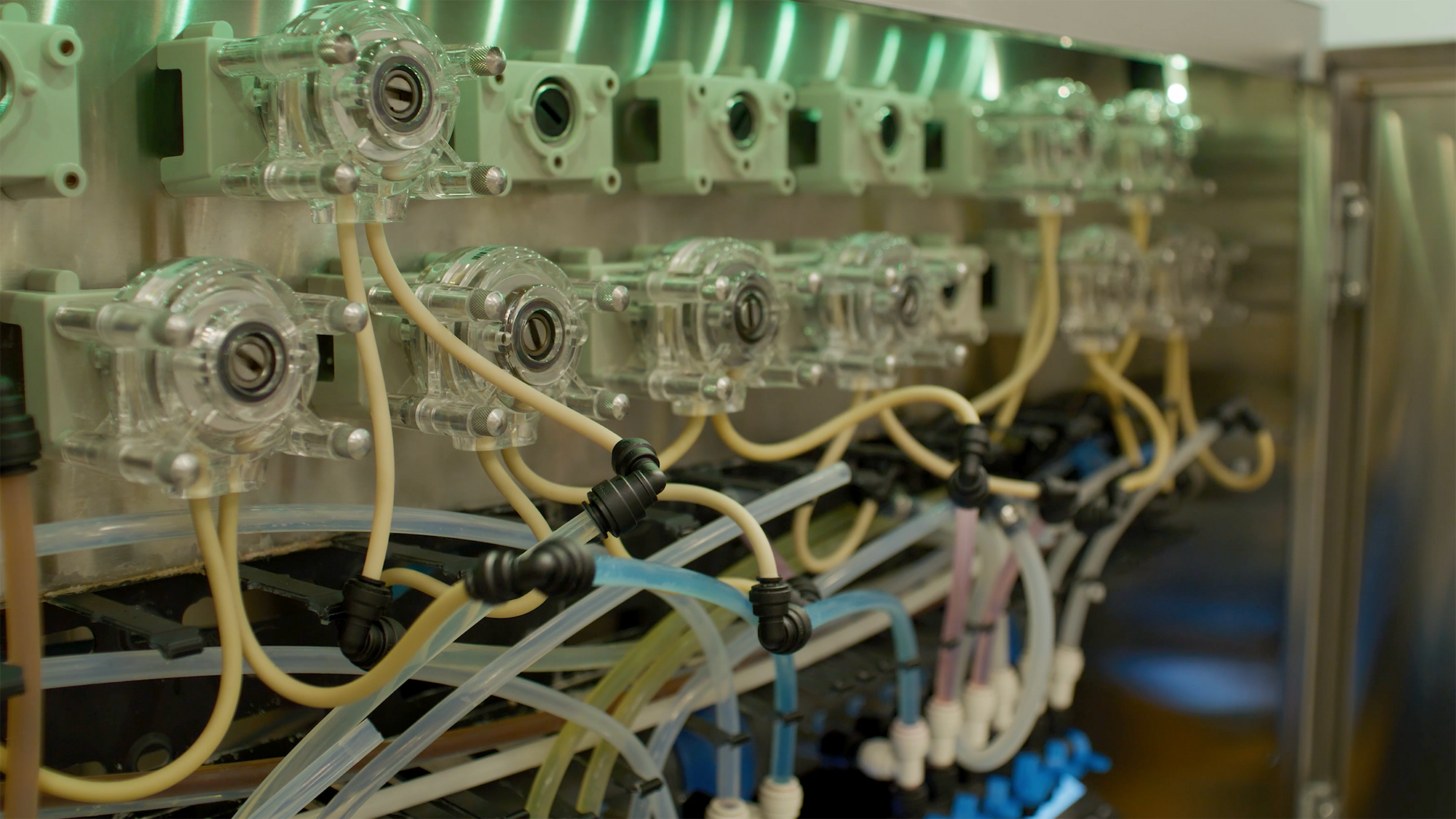

Operational bottlenecks often stem from the warm reservoir trap. When reservoir temperature control is neglected and the water climbs above 75 degrees, the facility enters a danger zone. Warm, nutrient-rich water is an excellent breeding ground for biofilm and root pathogens. These microorganisms grow exponentially in warm solution, consuming the oxygen intended for the plants and clogging precision drip emitters.

In practice, biofilm can establish anywhere you have moist, nutrient-rich plumbing. This is especially true in dark, low-flow lines, even if the bulk reservoir itself runs cooler. Once a biofilm takes hold in a system, it can reduce flow rates significantly, leading to uneven saturation across the crop. The biological activity in a warm reservoir can also lead to wild swings in nutrient availability as bacteria compete with the plant for essential elements.

Consider a large-scale commercial facility that neglected to insulate their main supply lines. The facility used a central batch tank, but the lines traveled 300 feet through a room that was heated to 85 degrees to support rapid transpiration. The data showed that while the water left the tank at a perfect 68 degrees, it reached the last bench at 78 degrees. The consequence was a massive inconsistency in crop height and quality. The plants near the tank were healthy, while the plants at the end of the line suffered from low oxygen and root stress.

Guesswork in thermal management leads to these invisible costs, where the facility pays for high-quality nutrients that the plants cannot access due to localized heat spikes. Maintaining a clean system during these spikes requires targeted tools: bio-enzymatic cleaners like BioFlo to keep reservoirs and irrigation lines free of biofilm and sludge, and root-zone enzyme products such as PhosZyme in the fertigation program to help release phosphorous from chemical bonds.

Thermal Precision: The Science Behind High-Strength Mixing

The Front Row Ag system is designed to provide high-strength mineral nutrition, but these advanced recipes require thermal precision to remain stable. The Direct To Reservoir (DTR) guide specifies a target temperature of about 71 degrees for the mixing process to help ensure chemical stability. When preparing a high-strength solution targeting a 3.0 EC, the water must have enough thermal energy to allow the dry minerals to dissolve within the recommended 3 to 5-minute agitation window.

In a standard high-strength recipe, the components contribute specific values to the total electrical conductivity. Part A is designed to contribute 0.322 EC for every gram added per gallon of water. Part B contributes 0.255 EC per gram, and the Bloom component adds 0.200 EC.

If the water is too cold during the mixing phase, these minerals may not fully dissolve. This leads to a solution that is lower in EC than intended, or a solution where minerals fall out of suspension and form a sludge at the bottom of the tank.

Furthermore, Front Row Si, applied in the 0–0.5 mL per gallon range based on your target feed EC (with typical values around 0.5 mL/gal at lower EC and tapering down as EC increases, per the Si vs. EC guidance in the DTR program), is a stabilized monosilicic acid. Like the rest of the Front Row system, it should be mixed into clean RO water around 71 degrees to ensure full dissolution and stability. Extreme thermal stress can cause even the most stable silica to lose its effectiveness, reducing the plant’s ability to resist environmental stress.

Because stabilized monosilicic acid is more sensitive to time in solution, any DTR reservoir that includes Front Row Si should be fully used within about 48 hours. Reservoirs mixed without Si can typically be held 5–7 days when stored in opaque, climate-controlled conditions. Aligning solution temperature and hold time with these guidelines keeps the chemistry predictable and repeatable.

Scientific literature on silicon confirms that its role in structural integrity and stress mitigation is vital for high-value crops. Thermal precision during mixing and storage ensures that the plant actually receives those benefits.

Advanced Protocols for Hydroponic Water Management

To maintain peak efficiency in a commercial facility, growers must implement universal best practices for managing the temperature of their nutrient delivery. These steps ensure that the physical delivery system matches the biological needs of the crop.

Maintain the 68-Degree Sweet Spot

The around-68-degree target is widely regarded as the practical sweet spot for hydroponic water management. At this temperature, the water is warm enough to facilitate rapid chemical reactions and mineral solubility, yet cool enough to maintain high levels of dissolved oxygen. In practice, keeping nutrient solution roughly in the 65 to 71-degree range with a target near 68 degrees ensures that the roots have the oxygen required for active transport and that the minerals are fully available in the solution. It is the point of maximum efficiency for both the chemistry of the tank and the biology of the root.

Insulate the Last Mile

The temperature in the batch tank is only part of the equation. Facility managers must ensure that the water temperature remains stable as it travels through the facility. This involves insulating main supply lines and keeping them off cold concrete floors or away from high-intensity heat sources. Protecting the last mile of the irrigation system ensures that every plant on the line receives the same metabolic cues. This uniformity is what separates elite growers from the rest of the market.

Thermal Buffering for Large Batches

Larger volumes of water are more resistant to temperature changes than smaller volumes. By utilizing large batch tanks, a facility creates a thermal buffer. Even if the ambient room temperature fluctuates, the high mass of the water will hold its temperature longer. This predictability allows the fertigation system to deliver a consistent recipe without the risk of mineral fallout due to sudden temperature drops. Using BioFlo regularly as part of this buffered system helps keep these large lines and tanks free of obstructions caused by biofilm and organic accumulation.

Calibration of Thermal Sensors

Precision requires accurate data. A thermal sensor that is off by even 2 or 3 degrees can mislead a grower into making incorrect adjustments. Regular calibration of all temperature probes ensures that the grower is reacting to real-world data rather than sensor drift. Consistent data is the foundation of any large-scale manufacturing environment, and commercial cultivation is no different.

Expert FAQ: Troubleshooting Temperature and EC

Why does my pH drift upwards when my reservoir gets warm?

As the temperature of the water rises, its ability to hold dissolved gases like carbon dioxide decreases. When carbon dioxide leaves the water, the acidity drops, causing the pH to rise. Additionally, warm water encourages microbial activity. As these organisms consume nutrients and release waste, they further destabilize the pH of the solution. This creates a cycle where the grower must constantly add acid to maintain the 5.8 target. Controlling temperature is often a more sustainable fix than chasing pH with acid.

The Feed Chart says to hit 2.4 EC during the standard program Stretch Phase; if my water is 55 degrees, should I just add more nutrients to compensate?

No. Adding more mineral salt to cold water will not fix the problem. If the water is too cold, the plant’s internal pump is essentially turned off. Adding more nutrients will only increase the osmotic pressure in the substrate, making it even harder for the plant to pull in water. You must first fix the temperature of the water into roughly the 65 to 71-degree range to allow the plant to utilize the minerals already present in the solution. Once the thermal bottleneck is removed, the existing EC will perform as intended.

Does water temperature affect how I use BioFlo for line cleaning?

Yes. BioFlo is an enzymatic and biological cleaner designed to digest biofilm and organic buildup in reservoirs and irrigation plumbing. Like the plant’s own metabolic processes, these enzymes are temperature-dependent. If the water is extremely cold, the cleaning action will be significantly slower. Running cleaning cycles at typical reservoir temperatures in the upper 60s to low 70s degrees ensures you avoid extreme cold and supports efficient enzymatic action, helping BioFlo clear irrigation lines of accumulated organic matter without needing a separate, special temperature setpoint.

Conclusion

In the competitive landscape of commercial specialty crop cultivation, predictability is the most valuable asset a manager can possess. By strictly controlling the water temperature in the hydroponic system, a facility eliminates one of the most common variables that lead to crop failure and inconsistent yields. Data-driven hydroponic water management transforms the cultivation process from a guessing game into a repeatable manufacturing environment.

When the metabolic throttle is set correctly, every other input works better. High-strength mineral recipes dissolve predictably, dissolved oxygen levels remain high, and the roots are empowered to drive the plant toward its full genetic potential. Precision in temperature control is not just about plant health; it is about protecting the return on investment for the facility and ensuring that every square foot of canopy is performing at its maximum capacity.

Embracing these thermal protocols provides the stability required to lead the market in quality and efficiency.

Are you ready to take the guesswork out of your facility? Apply for a commercial account today and get access to our expert technical advisors.